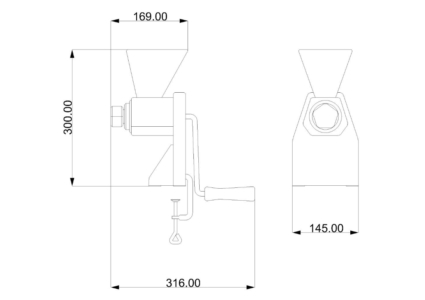

Fioccatrice Marga

Per ricavare farina integrale, fiocchi grossi o sottili.

Caratteristiche tecniche

- Movimento: manuale mediante manovella o in alternativa applicazione motore elettrico

- Misure: cm 31×12,5x22h

- Peso: Kg 2,5

- Regolazioni: n.3

La fioccatrice viene fornita completa di tramoggia, un contenitore per raccogliere i cereali macinati, la manovella e il morsetto.

Si può ottenere farina integrale (con cereali secchi), fiocchi grossi o sottili (con cereali morbidi).

La macchina è costruita in modo tale da poter macinare o schiacciare i cereali normalmente puliti.

Tuttavia, potrà succedere che i cereali in questione si siano seccati troppo. A questo si può rimediare lavando (non mettendo in ammollo) i cereali in un setaccio sotto l’acqua corrente, anche se essi sono già stati puliti. Il rivestimento esterno dei cereali diventerà più elastico permettendo una migliore preparazione dei fiocchi. Dopo questo lavaggio, lasciate riposare i cereali per alcune ore (meglio per una notte intera), avvolti in un canovaccio asciutto. Le prove da noi effettuate hanno dimostrato che i cereali freschi di raccolta possono essere macinati o schiacciati immediatamente.

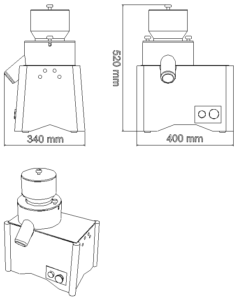

Electrical family mill (ME-6 Mod.)

Table mill also suitable for grinding corn.

Specifications

- Average grinding capacity 5 kg/hour (approximate value for wheat with an average fineness, it varies with finer and coarser flour setting and with other cereals)

- Grindstone: natural granite 15 cm diameter

- Rotations/min of grinding wheel: 320

- Engine: single phase 0.55 kw 220V 50Hz

- Buttons: low voltage (24V)

- Container: plywood treated with water-based paints

- Machine weight: 24 kg

- Overall dimensions: cm 34x40x52h

This machine is designed for grinding dry cereal (humidity below 14%).

The grinding of oats, soybeans, other oilseeds and legumes should be made with caution (only in case of very dry seeds and to obtain coarse grinding) because this makes the grindstones sticky.

The grinding is carried out through the rotation of a grinder on the other one, operated by an electric engine and by a toothed belt.

To achieve the desired consistency of the flour, act on the container of the grains.

By turning it clockwise the grinders approach each other and you get a finer flour. By reversing the rotation you get coarser flour.

Grind corn, if necessary, in several steps if the variety is very glassy; initially open the grinders in order to break the grains; sift and grind again the rougher part.

The mill produces whole flour. To get white or semi-whole flour use appropriate sieves.

Best if used in a well-ventilated area.

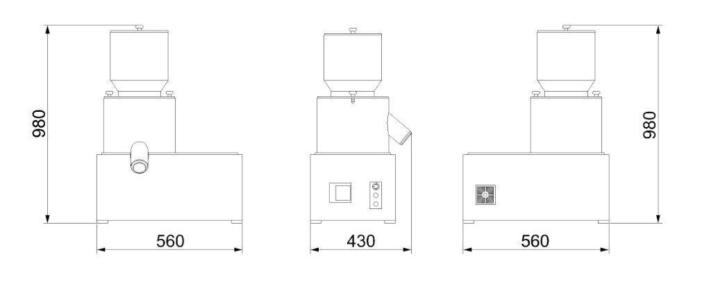

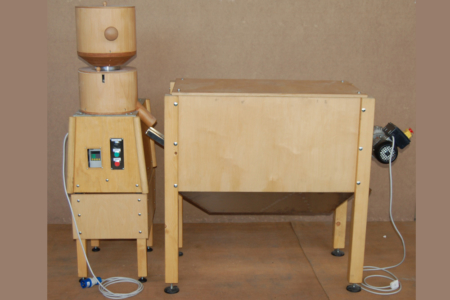

Electrical mill with inverter (ME-16-GR Mod.)

Semi-professional floor millwith adjustable rotation speed of the millstones.

Specifications

- Average grinding capacity: 20/25 kg/hour (approximate value for wheat with medium fineness, with adjustable inverter position 50 Hz, this value changes significantly based on the seetting of rotation and the distance between the millstones)

- Grindstone: natural granite 22 cm diameter 6 cm thickness

- Rotations/min of grinding wheel: minimum 130 maximum 392 depending on the setting of the inverter

- Engine: Kw 1.5 con alimentazione monofase 230V 50Hz

- Container: plywood treated with water-based paints

- Machine weight: Kg 90

- Overall dimensions: cm 56x43x98h. This machine is built with the ability to electronically change the number of rotations.

This machine is designed for grinding dry cereal (the grinding of oats, soybeans, legumes and the like must be done with great caution as it causes the bonding of the stones). Make sure that the machine is placed on a stable and robust base so as to support the weight and vibrations of the machine itself. Start the engine and then load the grain into the upper container after approaching a container to collect the flour below the outlet pipe.

To achieve the desired consistency of flour, act on the container of the grain.

By turning it clockwise the grinders approach each other and you get finer flour. By reversing the rotation you get coarser flour. It is very important to find the right balance between the openness of the millstones and engine rotation setting. The more you reduce the rotations, the more you can open the grinders, it is up to the operator’s experience to find the right balance between the two values in order to get the best result. The mill produces whole flour. To get white or semi-whole flour, use appropriate sieves.

Use in a well ventilated area.

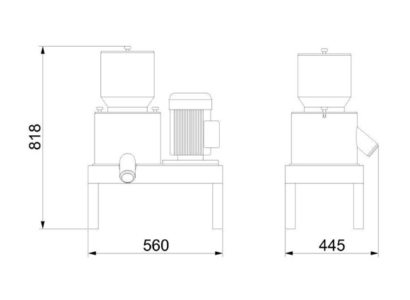

Electrical table mill (ME-16 Mod.)

Fixed-speed semi-professional table mill.

Specifications

- Average grinding capacity: 20-25kg/hour (approximate value for wheat with medium fineness, it varies with finer and coarser settings and with other cereals)

- Grindstone: natural granite 22 cm diameter 6 cm thickness

- Rotations/min of grinding wheel: 320 (fixed)

- Engine: single-phase 1.5 kW 220V 50Hz

- Containers:plywood treated with water-based paints

- Machine weight: 79 kg

- Overall dimensions: cm 56×44,5×81,8h

This machine is designed for grinding dry cereal (the grinding of oats, soybeans, legumes and other similar seeds must be done with great caution as it makes the grinders sticky).

Also suitable for grinding corn and durum wheat in small quantities.

Make sure that the machine is placed on a stable and robust base so as to support the weight and vibration of the machine itself.

Start the engine, then load the grain into the upper container after placing a container to collect the flour below the outlet pipe.

To achieve the desired consistency of the flour, act on the container of the grain.

By turning it clockwise, the grinders approach each other and you get finer flour. By reversing the rotation you get coarser flour.

The mill produces whole flour. To get white or semi-whole flour use appropriate sieves.

Best if used in a well ventilated area.

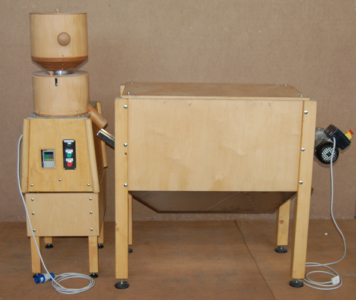

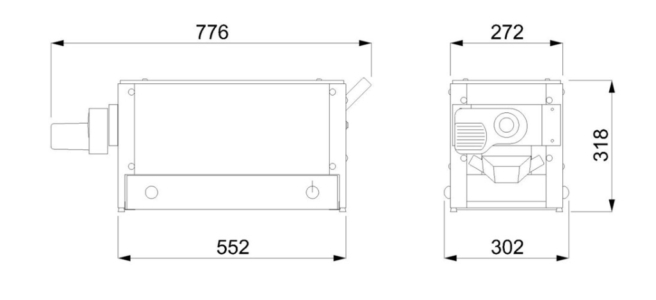

Electrical flour separator suitable for Me-6 mill

To divide the ground cereals into three parts: bran, middlings and flower.

Specifications

- Overall dimensions: cm 77x30x32

- Weight: Kg 10,400

- Material: plywood treated with water-based paints, stainless steel networks

- Engine: 230V 50 Hz 100W

- Amount: amount of separation max 10 kg/hour depending on the variety of cereal

- Applicable to the mill model Me-6 with appropriate supports

This machine is built with a rotating drum that separates the ground product into three parts, two parts go into the hopper, the third one (bran) comes out from the exhaust, so it is advisable to prepare a container for collection. Always turn on the separator before the mill or at least simultaneously. Make sure that the tray is not too full. During the grinding of corn you can combine both types of flour (finer and coarser flour). Upon request specific nets can be applied.

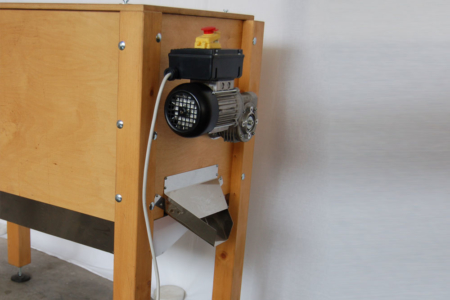

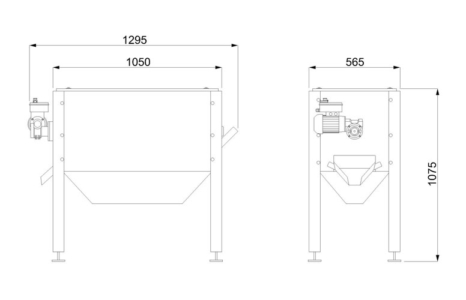

Electrical flour separator suitable for Me-16 mills

To divide the ground product into three parts: bran, middlings and flower.

Specifications

- Overall dimensions: cm 130x57x107

- Weight: kg 60

- Material: plywood with outer water-based paints

- Engine: single phase Kw 0.18 V 230-50

- Amount: amount of separation max 40 Kg/hour depending on the cereal variety

- Applicable to the table mill model Me-16 and Me-16 with adjustable rotation with appropriate supports

This machine is built with a rotating drum that separates the ground product into three parts, two parts go into the hoppers, near which appropriate containers for the collection must be placed, while the third part (bran) exits from the exhaust; also here it is useful to prepare a container for collection. Always turn on the separator before the mill or at least simultaneously. Make sure that the containers are not too full. During the grinding of corn you can combine both types of flour (finer and coarser flour). Upon request it is possible to apply specific nets.