Electrical model for the milk and fruit processing and slow pasteurization. 2 models available:

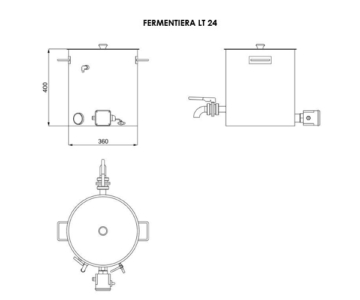

Fermenter Lt 24

SPECIFICATIONS

- Diameter: mm 360

- Total height: mm 400

- Tap: din 40

- Capacity: lt 24

- Max qty. product to be inserted: lt 20

- Weight: Kg. 11

- Electrical resistance: 3 Kw 230 Volt single phase

INTENDED USE OF FERMENTER

It is used for the transformation of milk into yoghurt or into some types of cheeses which have similar features. After making sure the fermenter is thoroughly clean, the necessary operations can be performed. Pour the water into the cavity through the inlet valve at the bottom of the fermenter up to the height of the drain. Alternatively, connect the same valve to a steam generator or hot water generator. Pour the milk into the fermenter ( please consider that the heating of milk involves a volume increase of about 3 mm per 10°C, so it is advisable not to load more than 50 liters, for the 60 lt version, and no more than 20 liters for the 24 lt version), place it on a flame or turn on the electrical resistance and start with the processing. Through the inlet valve at the bottom of the fermenter, it is possible to make the cold water flow in the cavity through a continuous cycle to get the cooling and the pasteurization of the product in the course of processing.

Fermenter Lt 60

SPECIFICATIONS

- Diameter: mm 468

- Total height: mm 557

- Total height roundup: mm 1100

- Tap: din 40

- Capacity: lt 6

- Max quantity of product to be inserted: lt 50

- Weight: Kg 38

- Cart weight: Kg 29

- Electrical resistance: Kw 5 Volt 400 three-phase

INTENDED USE OF FERMENTER

It is used for the transformation of milk into yoghurt or into some types of cheeses which have similar features. After making sure the fermenter is thoroughly clean, the necessary operations can be performed. Pour the water into the cavity through the inlet valve at the bottom of the fermenter up to the height of the drain. Alternatively, connect the same valve to a steam generator or hot water generator. Pour the milk into the fermenter ( please consider that the heating of milk involves a volume increase of about 3 mm per 10°C, so it is advisable not to load more than 50 liters, for the 60 lt version, and no more than 20 liters for the 24 lt version), place it on a flame or turn on the electrical resistance and start with the processing. Through the inlet valve at the bottom of the fermenter, it is possible to make the cold water flow in the cavity through a continuous cycle to get the cooling and the pasteurization of the product in the course of processing.